Plant Engineering

Plant engineering

Plant engineering refers to the design, construction, operation, and maintenance of industrial plants and manufacturing facilities. It involves various disciplines such as mechanical, electrical, civil, and chemical engineering, among others. Plant engineers are responsible for optimizing processes, ensuring safety and efficiency, and implementing technologies to improve productivity within the industrial setting. If you have any specific questions or need more information about plant engineering, feel free to ask!

Piping Engineering

Electrical Engineering

We Provide Power system studies, FEED and detail design for various onshore and offshore projects. The diversified team delivers power system solutions for complex plants, industrial and commercial applications. Deliver datasheets, cable, Earthing and Lighting layouts, MTO etc.

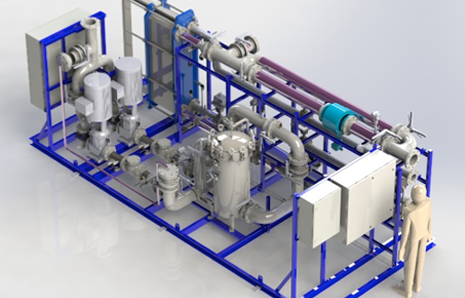

Compact Module Engineering & 3D Modelling

Our team expert in Modularization of packages, skids at offshore and onshore projects. Analysis to perform Lifting, In-place and Transportation conditions. Provide cost effective solution within assigned battery limits. 3D Modelling work by using S3D, E3D,PDMS,Autoplant and Tekla.

Instrumentation & Control Engineering

Our Design services includes Instrumentation and Process Control department performs conceptual and detail engineering and construction technical support associated with various Greenfield and brownfield projects. Areas of expertise include process control systems, Supervisory Control and Data Acquisition (SCADA), emergency Shutdown Systems (ESD), Distributed Control Systems (DCS), machinery protection and general field instrumentation. Deliver datasheets, Hookup, Installation drawings, I/O List, MTO etc.

Plant Safety

Asset Integrity Management Systems (AIMS) can be described as the capability of an asset to efficiently and effectively carry out its essential functions while ensuring the safety of people, the preservation of the environment, and the means to ensure that the individuals, processes, systems, and resources responsible for maintaining integrity are established, actively utilized, and reliable throughout the entire lifespan of the asset.

- HAZOP & HAZID Study

- SIMOPS & ENVID Study

- PHSER & QRA

- Third Party Design Review

- Gate Review Checks

- Constructability Review

- Project Health Safety and Environment Review (PSHER)

- Process Safety Management (PSM)

- Fire & Explosion Hazard Management (FEHM)

- Pre-commissioning OISD Audits

- HAZOP Training Programs and Workshops

- Comprehensive Safety Audits

- Fire Risk Assessment

- Safety Training Programs

- Value Engineering